|

|

| |

|

|

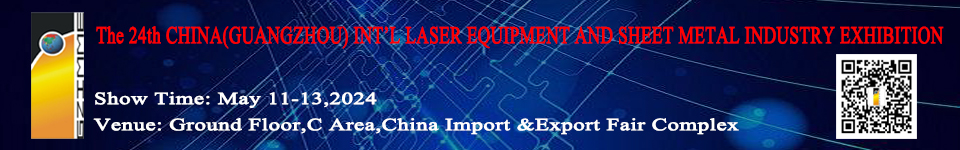

Sheet Metal Forming Processes – Recent Technological Advances-2024 China(Guangzhou) Int’l Laser Equipment and Sheet Metal Industry Exhibition

8/28/2023 钣金工业展-激光设备展-sheet metal expo-Laser expo |

--------------------------------------------------------------------------------------------------------------- |

|

|

The sheet metal industry has seen more technological advances than any other since the last century. Right from hand-forming processes to finite element based simulation, the transformation is very significant. They have prominent industrial applications especially in automotive industries. This may be attributed to the ease with which the final component with desired shape and appearance can be produced using simple tools. Due to wide range of applications, the process of forming the sheet metal into various shapes leads to classification of the forming processes based on specific operation. This classification involves bending, blanking, stretch forming and deep drawing. Each process has some parameters that define the quality of the work achieved. This paper aims at scattering light on the recent research and developments in the sheet metal forming processes over the last two decades. Most of the literature available on sheet metal forming focuses on the parameters that influence the quality and economic factor of the final product. The influence of process parameters based on geometry such as punch nose radius, blank temperature, and blank holding force, tooling dimensions, blank thickness and punch depth is significant. Similarly, the parameters based on the material properties like elastic strength, yield strength, plasticity and anisotropy have as much influence as the geometry based parameters. The literature raises the issue of defects in the formed parts. Defects such as wrinkling, tearing, springback, local necking and buckling in regions of compressive stresses have been analysed using both experimental and simulation techniques. Springback, the most predominant defect, has been researched thoroughly while considering sheet thickness, punch force, nose radius, binder force, die opening, punch velocity, punch height, sheet anisotropy, clearance, elastic limit and yield strength of the blank material as input parameters. Lastly, this paper also aims at reviewing the finite element based tool design, experimental and numerical investigations into sheet metal forming processes.

激光设备展-钣金工业展-2024第二十四届广州国际激光设备、钣金工业展览会-巨浪展览- 2024 China(Guangzhou) Int’l Laser Equipment and Sheet Metal Industry Exhibition

2024钣金展,2024钣金工业展 2024钣金展会,2024钣金展览会,2024激光设备展,2024激光设备展会,2024激光设备展览会,2024广州钣金展,2024广州钣金展会,2024广州激光设备展,2024广州激光设备展会,广东激光设备展,中国激光设备展会,广东钣金展,中国钣金展会,2024钣金展会信息,2024激光设备设备展,2024激光设备博览会,2024钣金博览会-sheet metal Industry Exhibition,sheet metal expo, 2024 sheet metal exhibition, 2024 sheet metal expo, China sheet metal exhibition, China sheet metal expo,-Laser Industry Exhibition,Laser expo, 2024 Laser exhibition, 2024 Laser expo, China Laser exhibition, China Laser expo

|

|

|

|

|